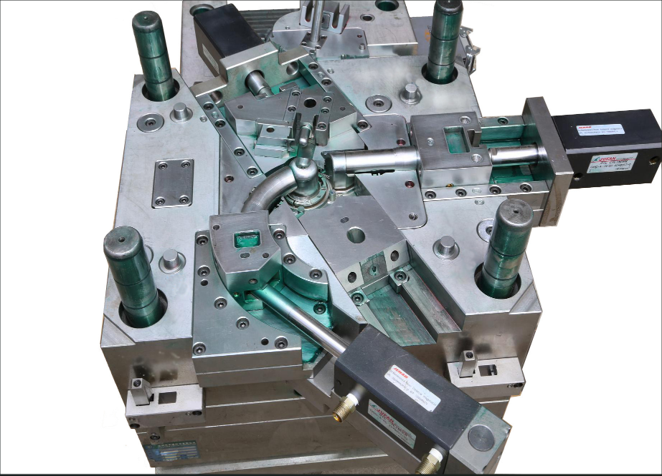

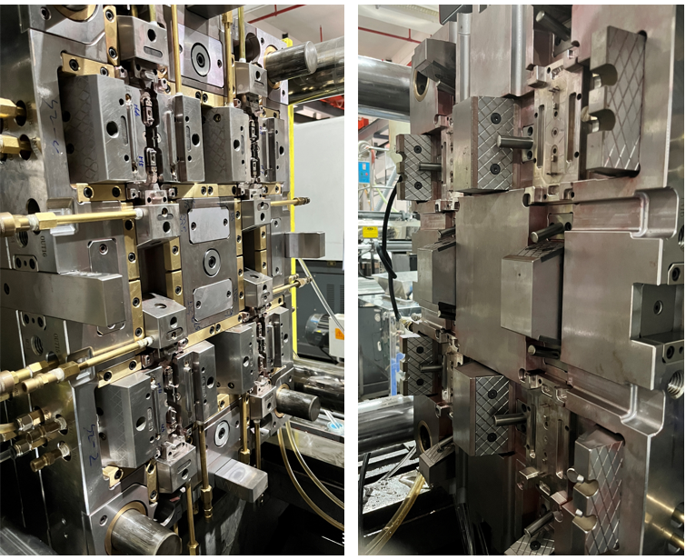

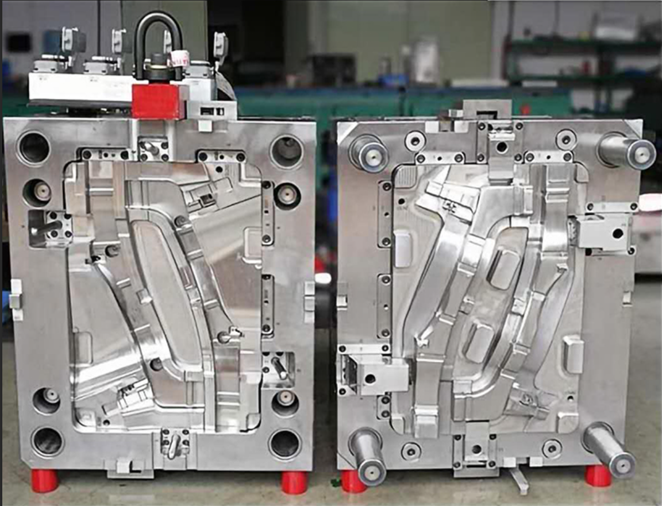

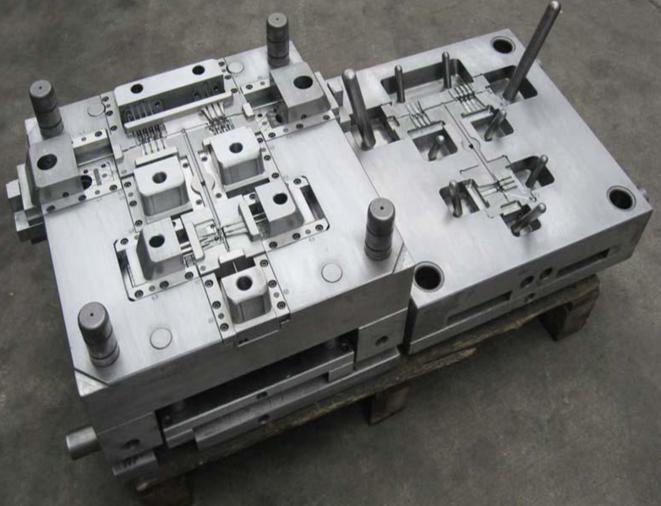

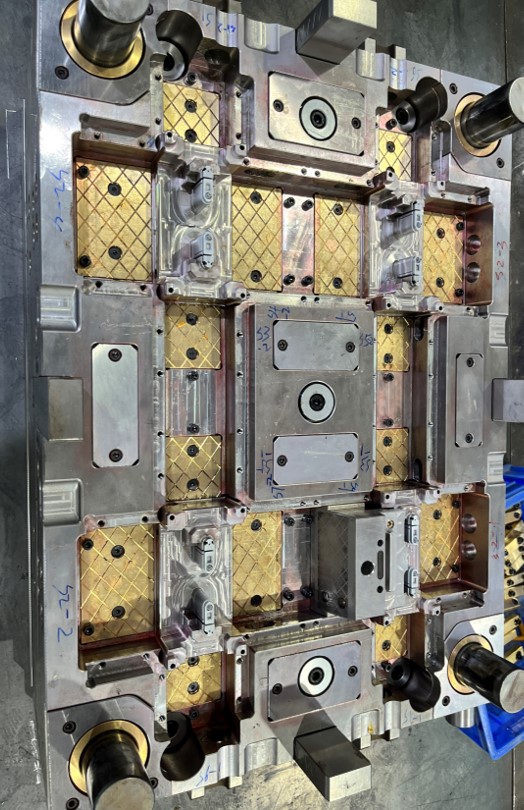

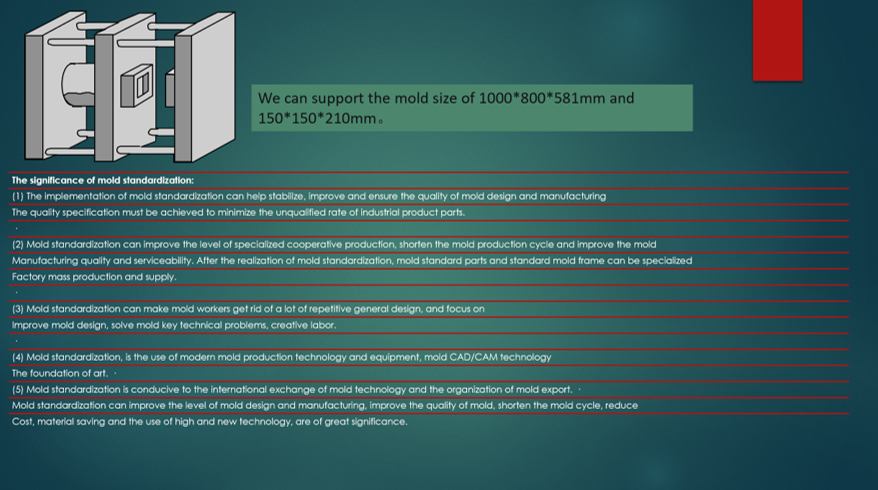

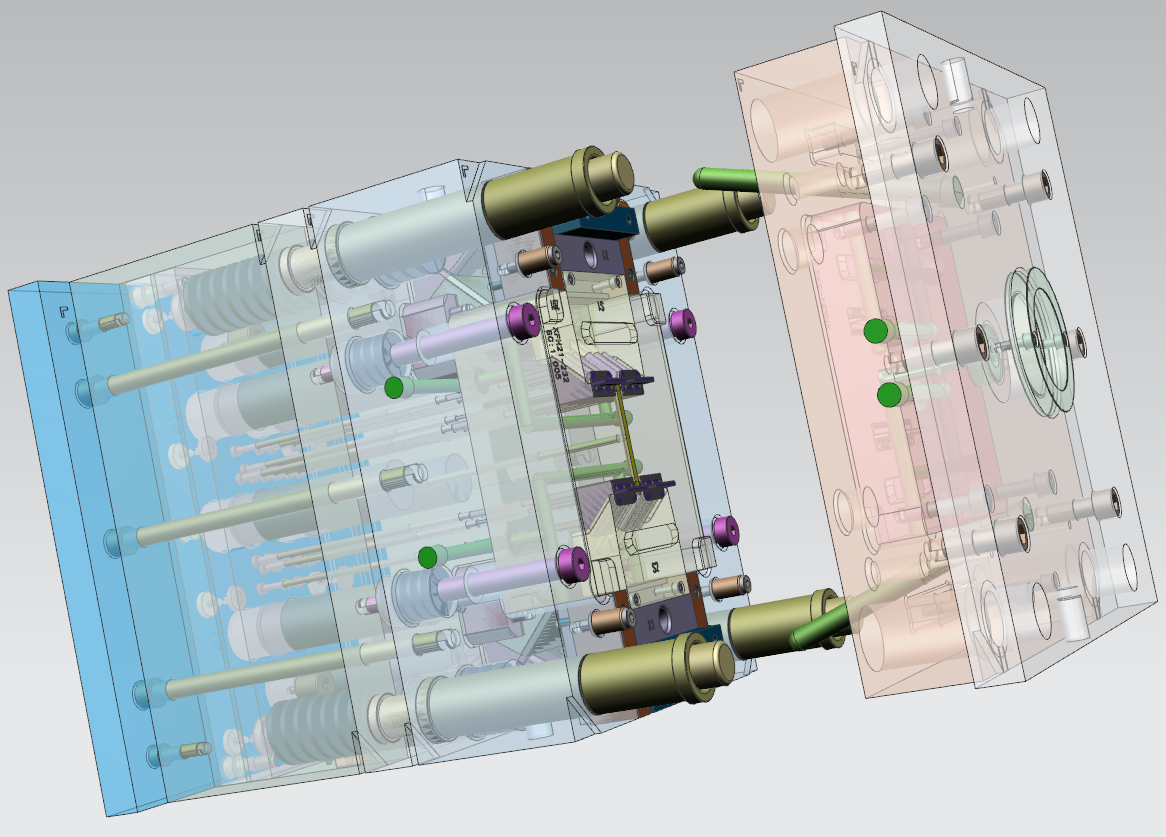

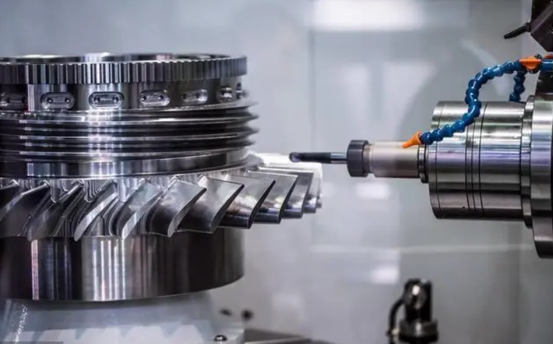

According to customer's requirement, make mold standard, fast mold,Hot-runner mold ,Quick exchange core mold ,Precision mold and Export mold,etc. In electronics, automobiles, motors, instruments, electrical appliances, meters, home appliances and communications and other products,60% - 80% of the parts are to rely on the injection molding, the production of parts by molding shows the high precision, high complexity, high consistency, high productivity and low consumption, can complete a variety of plastic parts.