| NO. | Design features | |

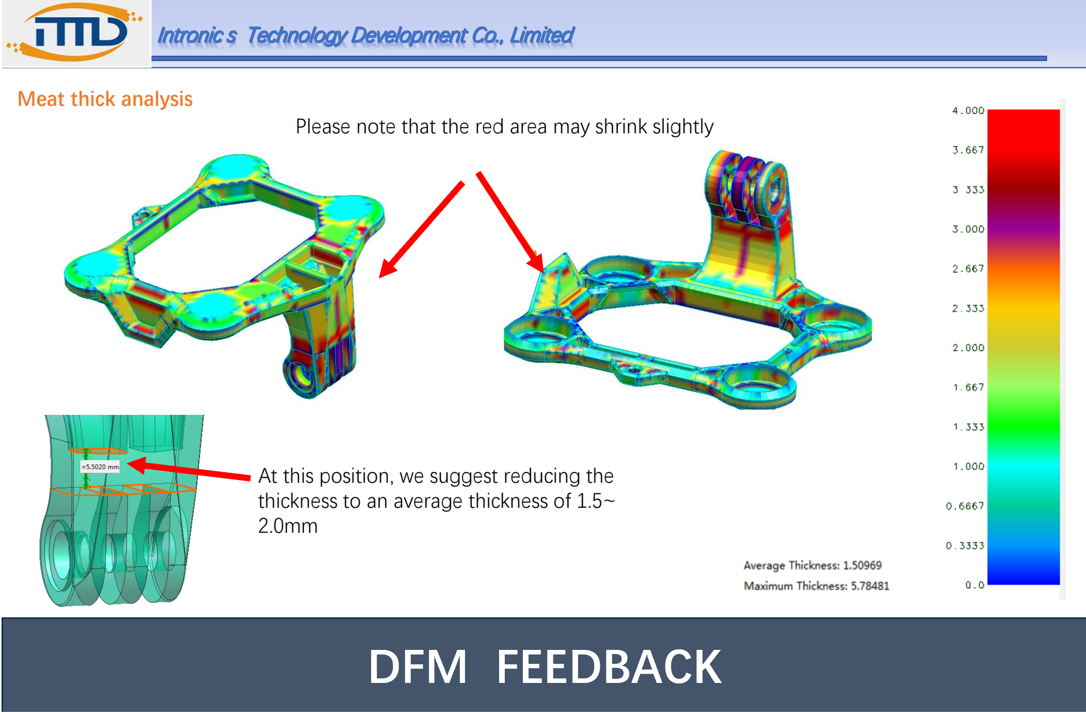

| 1 | Part Wall Thickness | Part should have uniform wall thickness throughout. This will help ensure the even distribution of the plastic during the injection molding process. Uniform wall thickness will also provide better structural stability.And you also The following table shows the wall thicknesses designed for the commonly used materials. |

| 2 | Gate Location | The gate, is the spot in the mold where the plastic resin is injected ,will leave a mark on the finished part.A good designer will place the gate in a location that is easy to remove, or better yet, in an inconspicuous spot so that it does not have to be removed. Eliminating the need for post processing will help reduce overall project costs. |

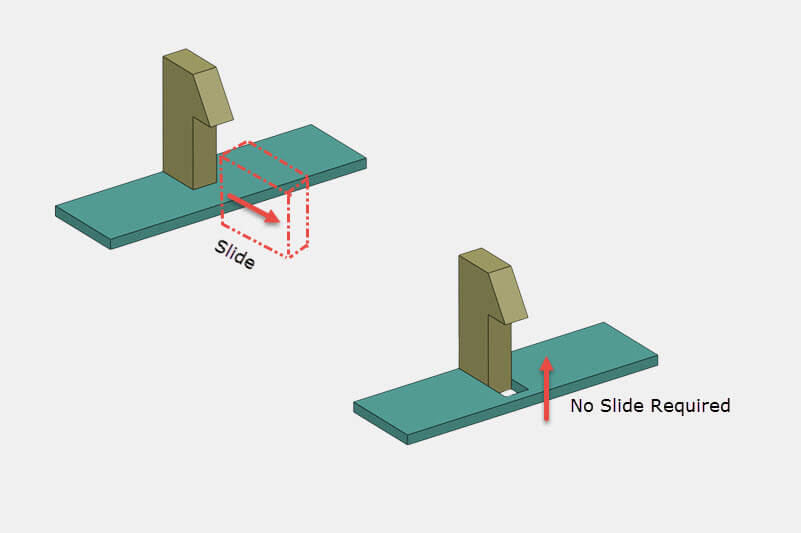

| 3 | Draft Angle | Good draft angles can save a lot of time and money for customer A positive draft angle will allow the part to be ejected from the mold easily. This will save wear and tear on the part and the mold and injection-molding machine. Generally,Draft angles should be around 1° to 2° and be considered for every wall on the part. But like MINIMUM FOR LIGHT TEXTURE (PM-T1/T2),the draft angle needs to be 3° or greater. |

| 4 | Bosses | notes:Proper bosses should have connecting ribs and be positioned away from sidewalls. Tthe designers should avoid merging bosses with sidewalls as they can form thick sections that lead to sinking. Bosses are a common feature in many plastic parts used as points for assembly. suggests setting the outside diameter of bosses at 2.0 to 2.4 times the outside diameter of the screw or insert to avoid Shrinking and cracking . |

| 5 | Shrinkage | All injection-molded pieces will have some shrinkage. The amount of shrinkage will depend on several factors but will mostly come down to the type of material being used. Shrinkage will happen to every plastic injection molded part because plastic will contract as it cools. During the design process, engineers must consider the shrinkage rate of material and accurately determine the shrinkage rate of the materials in order to prevent the products from being significantly larger or smaller than the intended size. |

| 6 | Ribs Features | Generally, the thickness of the Ribs should be the same as or slightly thinner than the wall thickness. If the Ribs are too thick, then obvious shrinkage marks will appear on the outer surface, and the Ribs should not be too deeper; otherwise, it will cause the mold to stick during mold release. |

| 7 |

此处是高级文本……

| Materials | Wall thickness recommended | Remarks | |

| ABS | 1.15mm - 3.55mm | ||

| PC | 1.00mm - 3.80mm | ||

| PP | 0.63mm - 3.80mm | ||

| PE | 0.76mm - 5.08mm | ||

| PS | 0.90mm - 3.80mm | ||

| Nylon | 0.76mm - 2.92mm |

此处是高级文本……