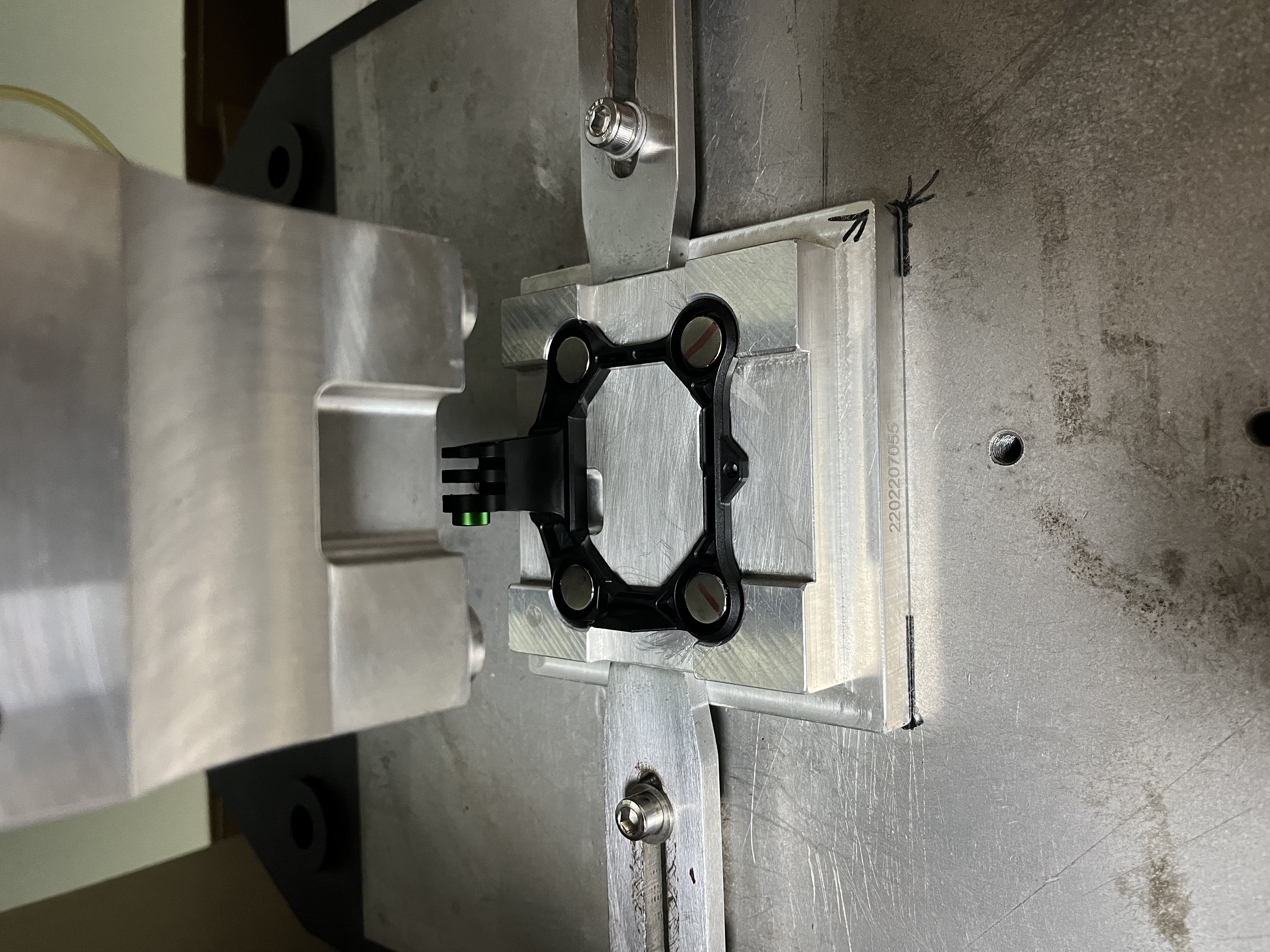

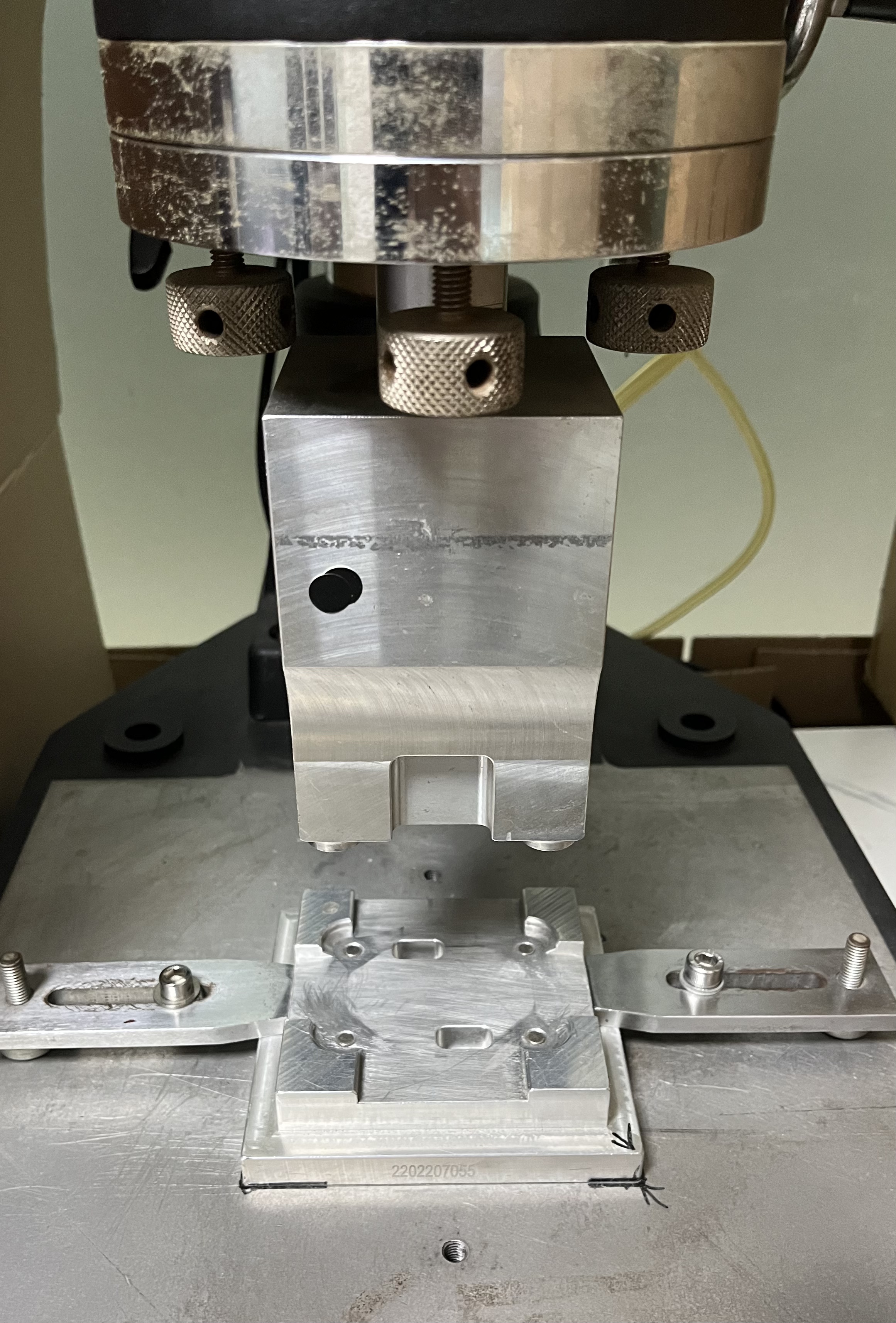

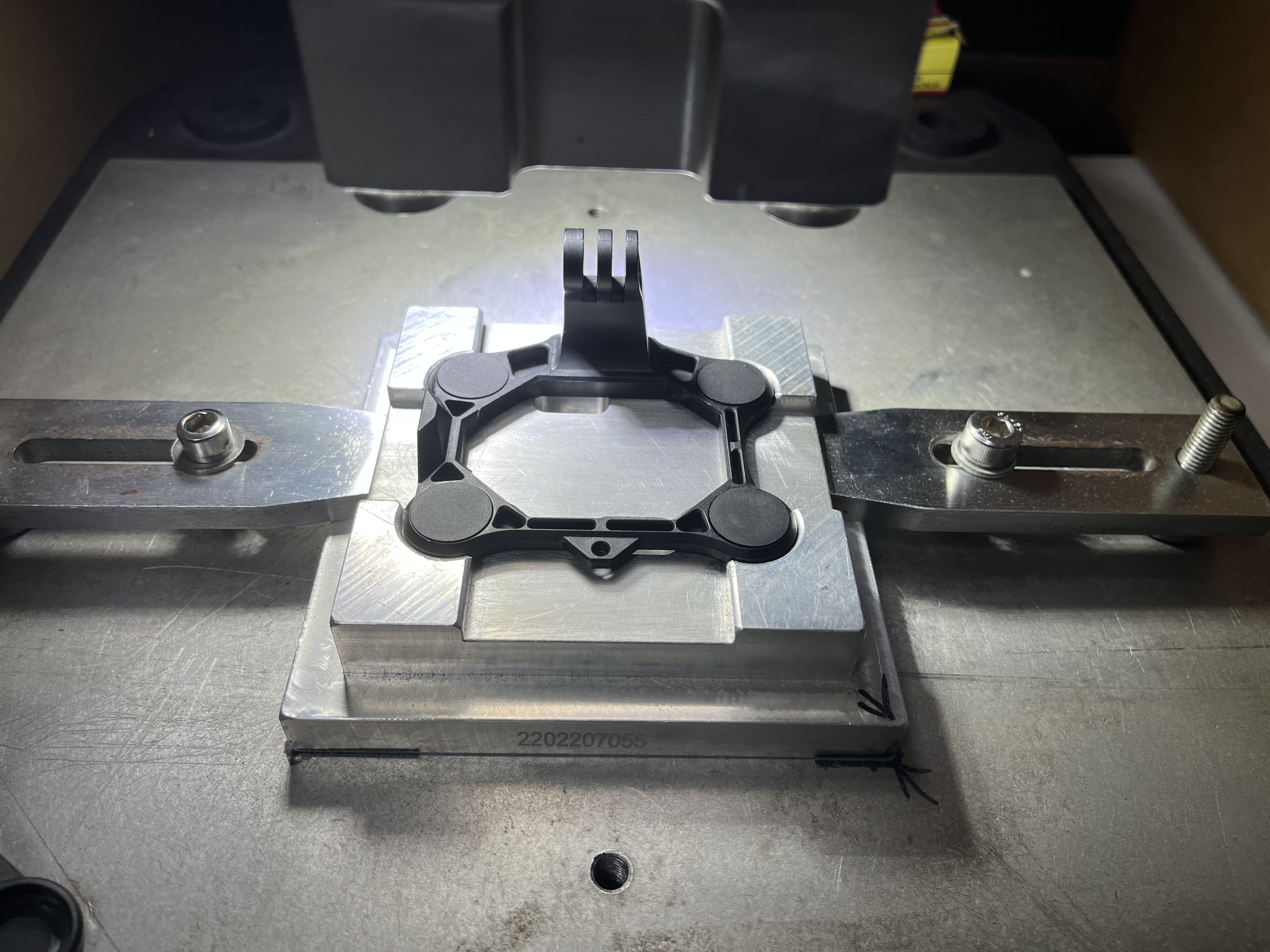

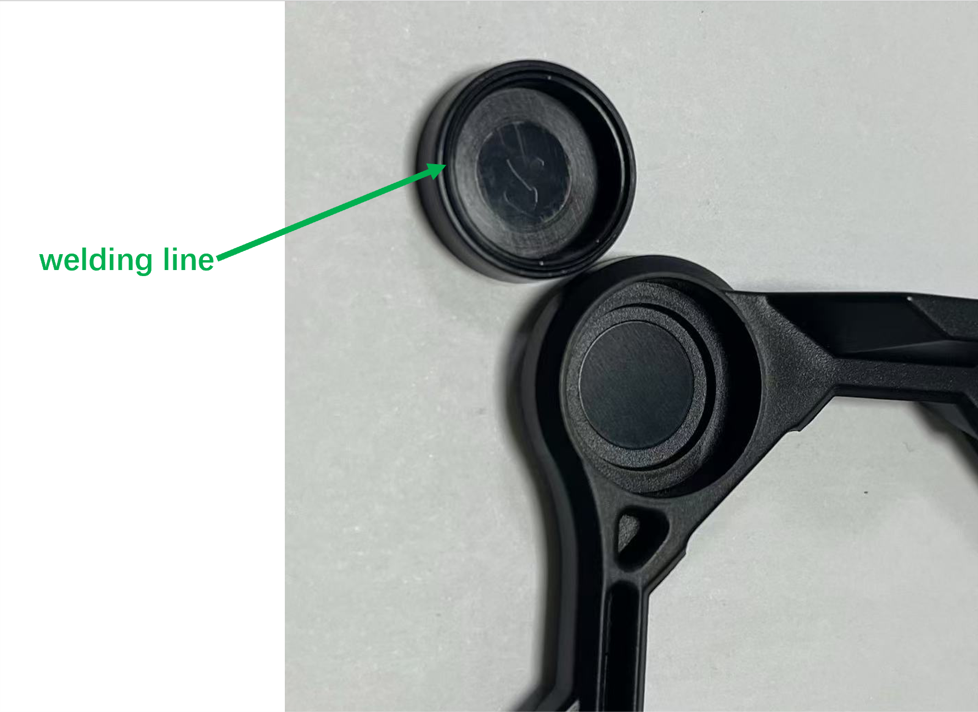

Ultrasonic welding is a high-tech process that can be applied to all thermoplastic products. The transducer converts high-frequency and high-voltage signals into high-frequency mechanical vibrations, which are applied to the plastic products, causing rapid friction between the two parts of the products so that the temperature rises. When the temperature reaches the melting point of the product itself, the interface of the product melts rapidly. At the same time, it is cooled and formed under a certain pressure to complete the welding.

When choosing the material for ultrasonic welding molds, the material of the ultrasonic welding head is generally magnesium, steel, titanium alloy, 7075 aluminum alloy, 6061 common aluminum material, etc. Among them, 7075 aluminum alloy is outstanding, as it has high hardness, strong heat conductivity and good toughness, making it very suitable for the material of ultrasonic welding heads. However, the main choice still depends on product requirements.