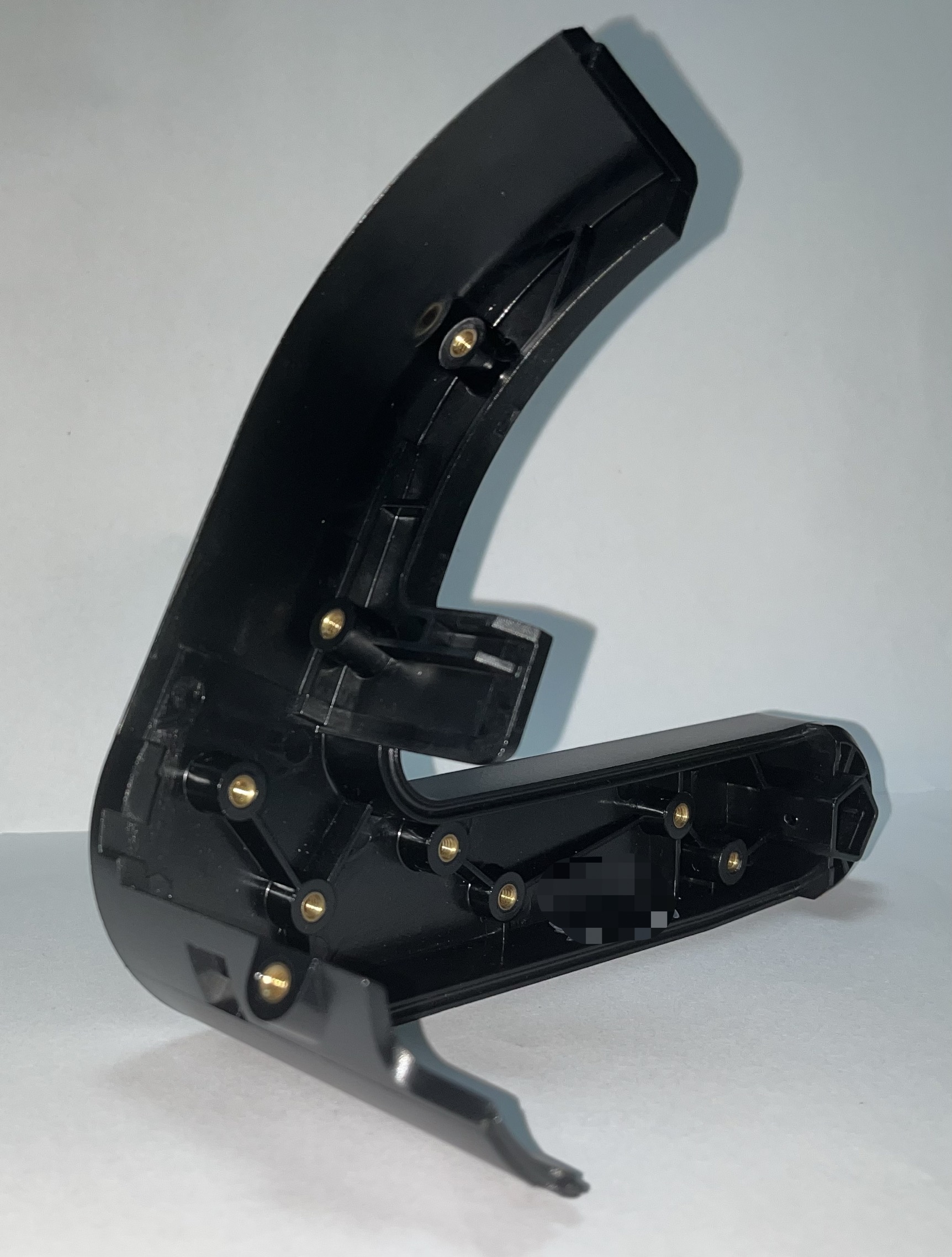

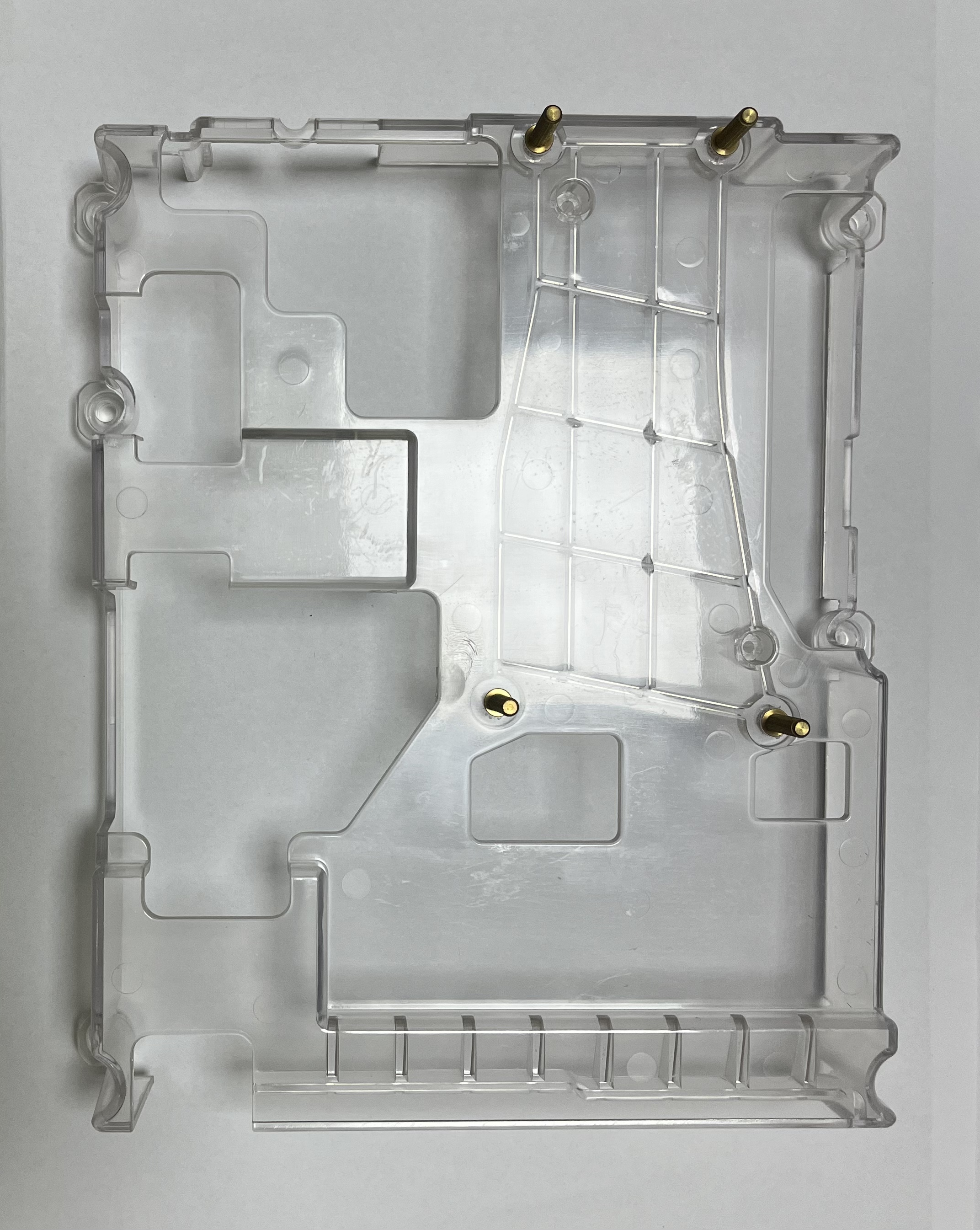

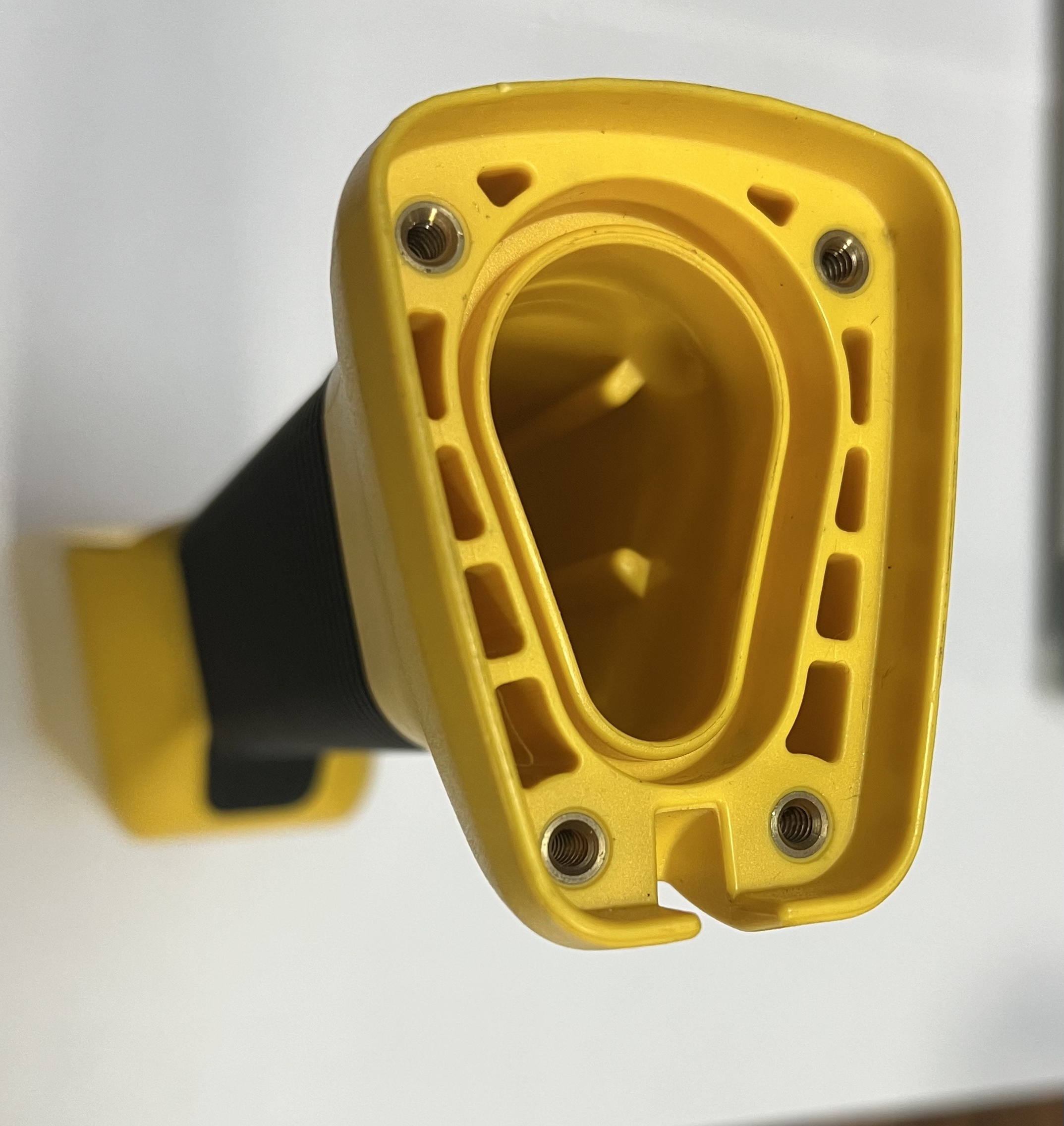

Insert injection molding is the process of molding a plastic part around a type of metal insert.Insert molding is an excellent way to replace metal parts with lighter-weight plastic versions that are just as strong.

Threaded inserts enable them to be attached to other components without cracking or damaging the plastic,and can reinforce the mechanical properties of plastic parts’ ability to be fastened together, especially over repeated assembly.

Bushings and sleeves inserted are another great way to increase part durability for mating components that need more abrasion resistance due to moving parts.

In addition, it enables you to design parts that wouldn’t be possible using either metal or plastic alone. It combines the best characteristics of both materials in an affordable, high-performance package.